Smart Factory

Intelligent equipment, intelligent production, intelligent creation

From a traditional factory to an intelligent chemical factory, we will use product digitization, production digitization, equipment digitization and management digitization to achieve the "six ones" digital management objectives: manage every employee → manage every order → manage every material → manage every process → manage every equipment → manage every fund, and the production management will be more precise, transparent and flexible!

Research and development

Continuous breakthroughs in R&D and innovation

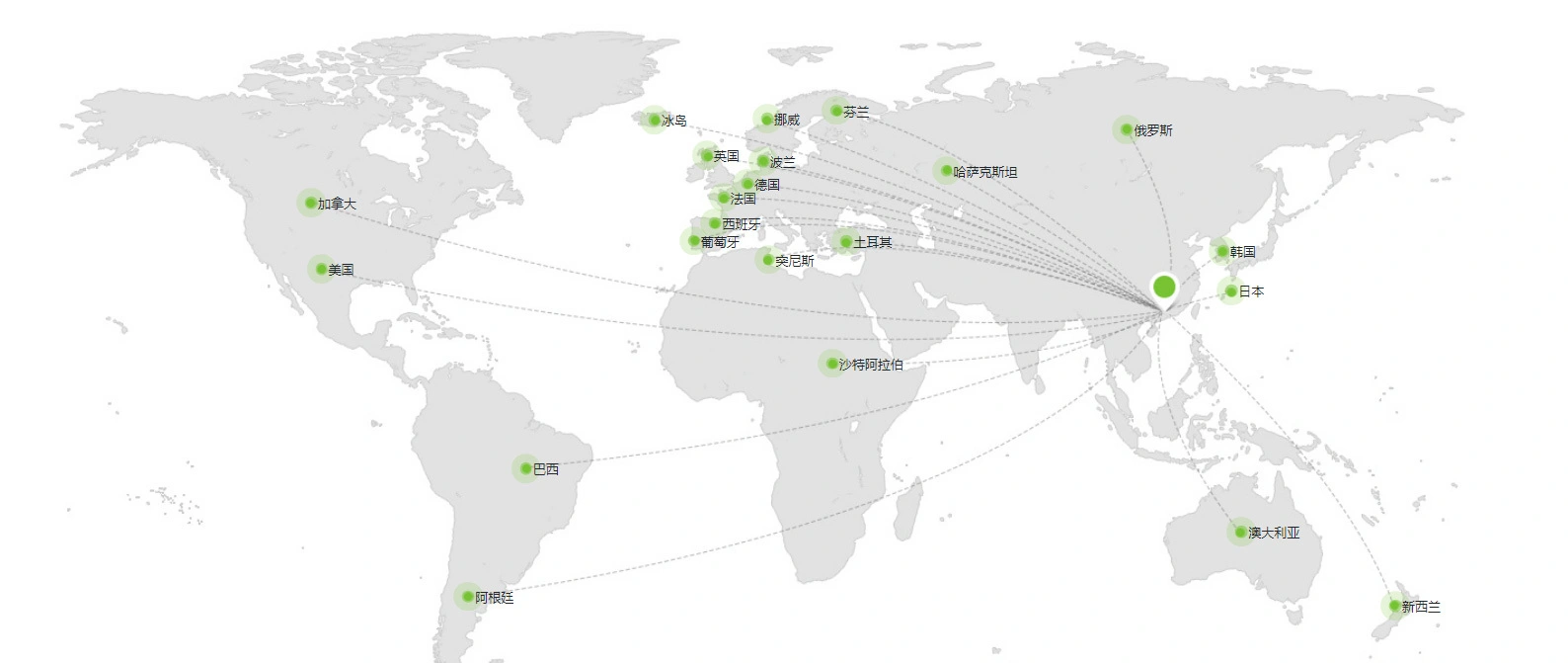

It pays attention to the collaborative development of production, research and research, cooperates with the presidents of many universities at home and abroad, and has a well-known professional think tank team at home and abroad integrating consultation, research and development, and sales, with an annual scientific research investment of more than 25 million yuan.

R&D team

Resume of experts and professors

President of Chinese Academy of Sciences

President of Chinese Academy of Sciences

President of Chinese Academy of Sciences

President of Chinese Academy of Sciences

R&D patents

More than 500 new products have been developed annually and nearly 100 patents have been granted

Now it has professional formula laboratory, process laboratory and testing center meeting the requirements of CNAS standards, which can carry out the research and development of formula design, process research, quality standard test, stability test and other projects of diversified products such as tablets, powders, soft capsules, hard capsules, oral liquid, etc.

With its excellent innovation and R&D capability,

Quality management system

Intelligent management

Integrated intelligent operation management platform